Adhesives & Sealants & Tackifiers, R&D, Coatings

Frequently asked questions about new transparent tackifiers Hydrogenated terpene/polyterpene resins

Adhesives & Sealants & Tackifiers, R&D, Coatings

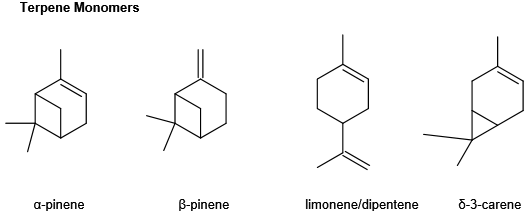

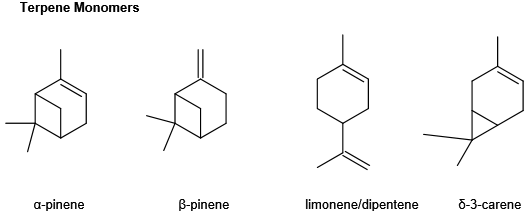

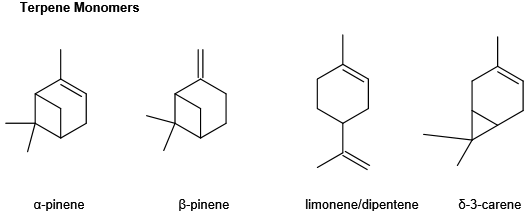

Hydrogenated terpene resins are made from the hydrogenation of polyterpene resins derived from gum turpentine oil obtained from pine tree. Gum turpentine mainly includes terpene monomers α-pinene,β-pinene, limonene/dipentene andδ-3-carene. There are mainly three types of hydrogenated terpene resins: Hydrogenated terpene resin/polymer, hydrogenated terpene phenol resin and Hydrogenated Aromatic Modified Terpene Resin.

They are transparent and widely compatible with various polymers, imparting excellent heat resistance, tack, and peel adhesion to PSA‘s and hot melt adhesives. Due to the high technical requirements and high cost level, there are very few suppliers in worldwide so far. We are exclusive supplier in China.

|

|

| Code | CAS No | Chemical Name | Appearance | Softening Point | Color | Packing |

| HTR105 | 106168-39-2 | Hydrogenated Terpene Resin | Flake | 95-105 | Hazen 50max | 25kgs kraft paper bags |

| HTR115 | 106168-39-2 | Hydrogenated Terpene Resin | Flake | 105-115 | Hazen 50max | 25kgs kraft paper bags |

| HTR125 | 106168-39-2 | Hydrogenated Terpene Resin | Flake | 115-125 | Hazen 50max | 25kgs kraft paper bags |

| HTP105 | 1254557-84-0 | Hydrogenated Terpene Phenolic Resin | Flake | 95-105 | Hazen 150max | 25kgs kraft paper bags |

| HTP115 | 1254557-84-0 | Hydrogenated Terpene Phenolic Resin | Flake | 105-115 | Hazen 150max | 25kgs kraft paper bags |

| HTP125 | 1254557-84-0 | Hydrogenated Terpene Phenolic Resin | Flake | 115-125 | Hazen 150max | 25kgs kraft paper bags |

Due to the high technical requirements and high cost level, there are very few suppliers in worldwide so far. We are exclusive supplier in China. As we know, Yasuhara Chemical in Japan is the earliest supplier of hydrogenated terpene resins. Our current grades are alternatives to CLEARON P series and YS POLYSTER UH.

| Advantages over hydrogenated rosin resins | Advantages over Hydrogenated hydrocarbon resins |

| 1. lighter color;

2. Higher tack and cohesion; 3. better stability and color retention, UV resistance; 4. better aging resistance; 5. higher SP and tg 6. wider compatibility, especially for hydrogenated terpene phenolic resin |

1. low-or-no VOC;

2. adhere well to various surfaces; 3. Bio-renewable, environmentally Friendly; 4. Higher SP and tg 5. wider compatibility, especially for hydrogenated terpene phenolic resin 6. Wider usability |

| Product | Applications | Industries |

| Hydrogenated Terpene Polymers HTR105, HTR115,HTR125 | A. Optical pressure-sensitive adhesive, UV adhesive, hot-melt adhesive, especially for natural and synthetic rubber-based adhesives

B. Optical resins, photocurable resin C. Polymer modifier to improve flow, optical D. Soldering flux |

a) Medical: Medical adhesive patch…

b) Electronics: Optical acrylic pressure-sensitive adhesive tape for crystal display devices assembly, Soft photo-curable resin filled between touch panel and a display element… c) Cosmetics: mascara… d) Automobile: automobile lamp assembly… |

| Hydrogenated Terpene Phenolic Resins HTP105, HTP115,HTP125 | A. Pressure-sensitive adhesive, UV adhesive

B. Optical resins C. Polymer modifier |

a) Automobile: protective film for OA equipment, automotive coating..

b) Electronics: double-side adhesive sheet for fixing liquid crystal display panel holding flexible printed circuits with backlit panel frame… c) Glass, plastic, rubber, coating, paints, inks… |