Industry News, Adhesives & Sealants & Tackifiers

Market Trends: Multiple Factors Driving Growth for Electronics Adhesives

Industry News, Adhesives & Sealants & Tackifiers

Link: Market Trends: Multiple Factors Driving Growth for Electronics Adhesives | ASI

By: Nikhil Kaitwade, FMI

Adhesives are widely used in the electronics industry for bonding surface mount components, wire tacking, conformal coatings and encapsulating components. Adhesives impart a host of properties to electronics, such as electrical and thermal conductivity. High demand for consumer electronics, especially in developing countries, has provided an impetus to the global electronics adhesives market.

The Asia-Pacific region is of prime significance to the electronics adhesives market. Home to two of the world’s most populous nations, China and India, the region generates high demand for a plethora of electronic products. Demand for automotive and consumer appliances products—two major end-use applications of the electronics adhesives market—is expected to boost the market in the Asia-Pacific region.

Increasing demand from end-user industries has also meant that more players are entering the business of raw material manufacturing. The entry of local and multinational players has ensured uninterrupted supply to electronics adhesives manufacturers.

One of the biggest challenges for the growth of the electronics adhesives market is regulations governing volatile organic compound (VOC) emission limits. Adhesives films, which constitute a major part of electronics adhesives, have come under scrutiny due to these regulations, and this can restrain the growth of the market.

Mergers and acquisitions (M&A) are a key trend in the electronics adhesives market. Both local and international players are looking to expand their product lines and technological capabilities; this is the main reason for the pervasiveness of mergers and acquisitions in the market. For example, the acquisition of Switzerland-based Forbo Group by H.B. Fuller Co. in 2012 was aimed at increasing production capacity, as well as consolidating their position in the market.

The use of advanced acrylics in electronics adhesives is another key trend in the market. Advanced acrylics are superior to hot-melt and traditional adhesives, as they offer reduced curing time and quicker bonding.

Another key trend in the electronics adhesives market is the emphasis on research and development (R&D). Manufacturers are working with universities to develop innovative electronic components and devices. R&D spending by key players accounted for around 7% of the total revenue generated in 2014.

The global electronics adhesives market is projected to witness a compound annual growth rate (CAGR) of over 12% through 2020, to reach a valuation of $6.2 billion. The global demand for electronics adhesives is projected to reach 1.9 million tons by 2020.

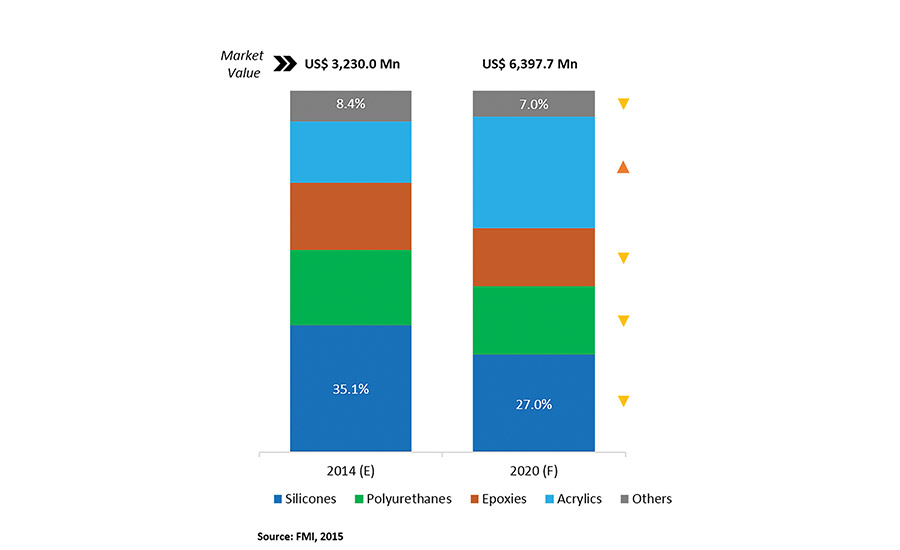

Figure 1. Market Value of Electronics Adhesive 2014~2015, © FMI

Silicones is the most dominant segment in the global electronics adhesives market. The segment’s value was $1.1 billion in 2014. It is projected that the silicones segment will witness a CAGR of nearly 7% through 2020 and reach a valuation of $1.7 billion. The acrylics segment is anticipated to expand at a whopping CAGR of more than 20% and reach a valuation of nearly $2 billion by 2020. Polyurethanes and epoxies segments are also projected to witness strong CAGR until 2020.

The electrically conductive segment is projected to expand at a CAGR of more than 16% through 2020. It is projected that the electrically conductive segment will reach a valuation of over $2 billion. The ultraviolet-curable segment is projected to witness a CAGR of over 7% to reach a valuation of over $1 billion by 2020.

In application segments, conformal coatings had the largest market value in 2014. The conformal coatings segment is projected to witness a CAGR of approximately 11% through 2020 and reach a valuation of $1.8 billion. Surface mounting is projected to witness the highest CAGR on account of “miniaturization,” a key trend in the electronics industry. Encapsulation and wire tacking segments are also expected to witness double-digit CAGR through 2020.

Asia-Pacific is the most lucrative region for the worldwide electronics adhesives market. Some of the leading electronics component manufacturers have a strong presence in the Asia-Pacific region. The region accounted for a market share of over 60% in 2014, and it is projected that it will continue to be the most dominant market for electronics adhesives through 2020. Valued at $1.9 billion, the electronics adhesives market in the region is anticipated to witness a CAGR of approximately 13% and a valuation of $4 billion by 2020.

Following Asia-Pacific is Europe, where the market is anticipated to be worth $815 million by 2020. The growth of the electronics adhesives market in Europe is fuelled by strong demand from manufacturers in the UK, Germany and Russia. Other key regions for the electronics adhesives market include North America and Latin America. The electronics adhesives market in both these regions is poised to witness high single-digit CAGR through 2020.

Copyright of this article by ASI. We are sharing and promoting the market innovation.

If you like this article, kindly to visit www.adhesivesmag.com